What is CNC Machining?

CNC (Computer Numerical Control) Machining is a manufacturing process in which pre-programmed computer software dictates the movement of factory tools and machinery. It’s used to control complex machines that perform a variety of functions, such as drilling, turning, milling, and routing. CNC machining allows for precise and repeatable production of parts by controlling the movement of machines along multiple axes to cut or shape materials to exact specifications.

Online CNC Machining Services for Custom Parts

CNC Machining Solutions

3-Axis CNC Milling

3-axis CNC milling services offer precision machining for simple geometries, providing high-quality parts with accurate cuts and smooth finishes, ideal for flat surfaces, slots, and drilled holes.

4-Axis CNC Milling

4-axis CNC milling services enable precise machining on complex parts by adding rotational capability, ideal for components with cylindrical or symmetrical shapes.

5-Sided Machining

5-sided CNC machining services streamline production by allowing multi-sided machining in a single setup, enhancing efficiency and accuracy for box-like and larger parts.

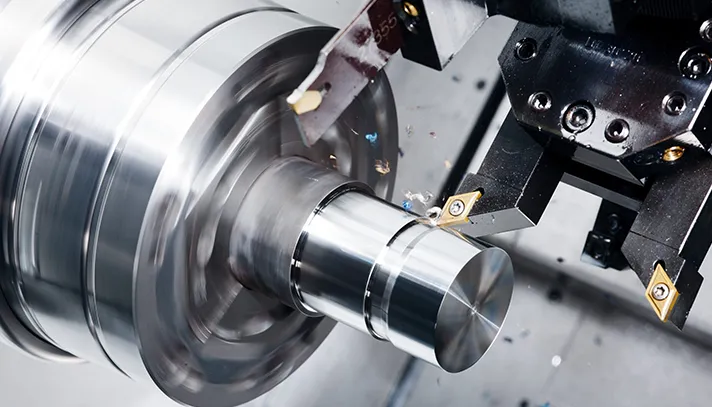

CNC Turning

CNC turning services deliver high-precision, round parts with smooth finishes, perfect for complex, cylindrical components across various industries.

CNC Preparation Work

Tolerances for CNC Milling

Yuhui ensures accuracy through our CNC milling tolerance standards. We are committed to accurate measurements that provide our customers with consistent, high-quality results and are optimized for search visibility.

| 3-Axis | 4-Axis | 5-Sided | |

| Maximum Part Size | 2000*1000*500mm | 1000*500*500mm | 1000*500*500mm |

| Minimum Part Size | 5*5*5mm | 5*5*5mm | 5*5*5mm |

| General Tolerances | ±0.01mm | ±0.05mm | ±0.05mm |

CNC Machining Department

Yuhui's CNC workshop is equipped with more than 50 advanced CNC equipment, including 3-axis, 4-axis and 5-Sided CNC machining equipment, which can achieve high-precision processing, with an accuracy range of 0.01~0.03mm and a surface roughness of Ra0.3-1.6μm.

Our facilities aren’t limited to just basic CNC machines. We also have a variety of high-precision equipment such as grinders and wire cutting to meet the precision processing needs of complex parts. Through automated production lines, we can improve production efficiency while ensuring accuracy and meet the rapid delivery requirements of large-volume orders. With nearly 30 years of industry experience, our technical team provides a full range of CNC processing services, which are widely used in many high-end industries such as automobiles, aviation, and medical.

27 +years

Of experience

2500T

Capable of producing

20000 +㎡

Production Workshop

Small Molded Parts with in Days

Our complete CNC aluminum service will accompany your aluminum machining project from the prototype construction to the end aluminum parts manufacturing.

Get a Quote

Different Types of CNC

CNC Milling Services

CNC milling is a precise manufacturing process where a computer-controlled machine removes material from a workpiece. Guided by a computer program, the cutter's movement is highly accurate and repeatable. CNC milling is ideal for creating complex shapes and designs, making it widely used in aerospace, automotive, and medical industries where precision and consistency are critical. This process enables manufacturers to produce high-quality parts with minimal waste and maximum efficiency.

CNC Turning Services

CNC turning is a machining process where material is rotated against a cutting tool to remove material from a workpiece. This process is ideal for creating cylindrical or round parts, such as shafts, rings, and other rotationally symmetrical components. Computer-controlled instructions guide CNC turning, ensuring precise, repeatable cuts and smooth surface finishes. This process is highly efficient, allowing for rapid production of complex designs with tight tolerances. CNC turning is commonly used in industries like automotive, aerospace, and medical manufacturing, where high-quality, accurate components are required.

Material

Aluminum Alloy

Aluminum casting offers a lightweight, corrosion-resistant solution with excellent thermal conductivity and recyclability, making it suitable for a wide range of applications.

Aluminum ADC12, ADC6, A360, A380

Zinc Alloy

Zinc alloy casting provides high precision and excellent flowability for intricate designs, along with good corrosion resistance and lower production costs.

Zinc Zamak 3, Zamak 5, Zamak 2, ZA8

Eight Processes

High-accuracy aluminum and zinc alloy parts produced with state-of-the-art die casting machines ranging from 88T to 2000T.

Read More

With machines from 88T to 2000T, we produce high-accuracy aluminum and zinc alloy parts efficiently.

Read More

Over 50 CNC machines, including 3-axis, 4-axis, and 5-axis, deliver precise and efficient machining for complex components.

Read More

A combination of manual and automated deburring techniques ensures smooth, defect-free surfaces for optimal performance.

Read More

Post-casting reshaping and alignment guarantee dimensional accuracy and structural integrity.

Read More

Comprehensive finishing solutions, including powder coating, spray painting, and UV coating, ensure superior durability and aesthetics.

Read MoreSolution

Product

FAQ

Q: What is the precision of your CNC machining?

+ -A: Our CNC machining tolerance can reach ±0.01mm, and we offer higher precision customization based on customer requirements.

Q: What materials can you machine?

+ -A: We can machine a variety of materials, including aluminum alloys, zinc alloys, stainless steel, copper, and plastics, catering to different industry needs.

Q: What CNC machining services do you offer?

+ -A: We offer a variety of machining processes, including turning, milling, drilling, tapping, and boring, with support for 3-axis, 4-axis, and 5-axis machining.

Q: How do you ensure the surface quality of machined parts?

+ -A: We use high-speed cutting, precision tools, and coolant control to ensure a surface roughness of Ra 0.8 or lower.

Q: Do you support small-batch custom machining?

+ -A: Yes, we accept orders from small to large batches and offer flexible production schedules.

Q: How do you control thermal deformation during machining?

+ -A: We minimize thermal deformation and enhance dimensional stability by optimizing cutting parameters, using coolants, and refining machining paths.

Q: Does your CNC machining comply with ISO standards?

+ -A: Yes, our machining processes comply with the ISO 9001:2015 quality management system to ensure consistent product quality.

Q: Do you provide quality inspection reports for CNC machining?

+ -A: We provide comprehensive quality inspection reports, including dimensional measurements, surface roughness analysis, and material composition testing.

Q: Can you machine complex 3D curved parts?

+ -A: Yes, our 5-axis CNC machining capabilities allow precise control of complex 3D surfaces, making it suitable for aerospace, automotive, and other industries.

Put Your Parts Into Production Today

Get a Quote

Get in Touch

If you cannot find a suitable product, please leave a message or contact us. We have a dedicated technical team to serve you.