What is Deburring?

Deburring is the process of removing excess metal burrs, sharp edges, or protrusions from the surface or edges of a workpiece that are formed during manufacturing processes like cutting, milling, stamping, or drilling. These burrs can affect the part's function, appearance, and safety, so deburring is essential for ensuring the part meets quality and performance standards.

How Do We Deburr the Parts

01

Grinding

The first step involves grinding to remove larger burrs and surface irregularities, smoothing out the surface initially. This process typically uses sandpaper, grinding wheels, or mechanical grinders to remove excess material while preserving the shape and precision of the workpiece.

02

Polishing

After grinding, polishing is carried out to enhance surface smoothness. This step removes fine scratches, creating a polished finish with the desired shine and appearance. Polishing often utilizes buffing wheels and polishing compounds and is crucial for detailed finishing.

03

Sandblasting

The final step, sandblasting, involves spraying abrasive materials at high speeds onto the surface, achieving a uniform matte finish while further cleaning the surface. This process removes any remaining fine particles, enhances wear resistance, and creates a texture ideal for coating adhesion.

Grinding Equipment

Yuhui Deburring is proud to offer contract deburring services in accordance with ISO 9001 standards for the removal of machine burrs from die castings and selected metals. Currently operating two production lines:

Automatically Grinding

High Precision and Consistency

Robotic deburring ensures precise, consistent results by minimizing human error and maintaining high accuracy across all parts, meeting stringent quality standards.

Stability of Robotic Process

Robots offer reliable, error-free performance over long periods, ensuring stable operation without the inconsistencies introduced by manual labor.

Flexibility and Versatility

The robotic system adapts easily to different parts and shapes, offering tailored deburring solutions for complex geometries and varying surface requirements.

Efficient Production and High-Volume Processing

Robots increase production efficiency by processing high volumes of parts quickly, reducing cycle times, and ensuring faster delivery of high-quality products.

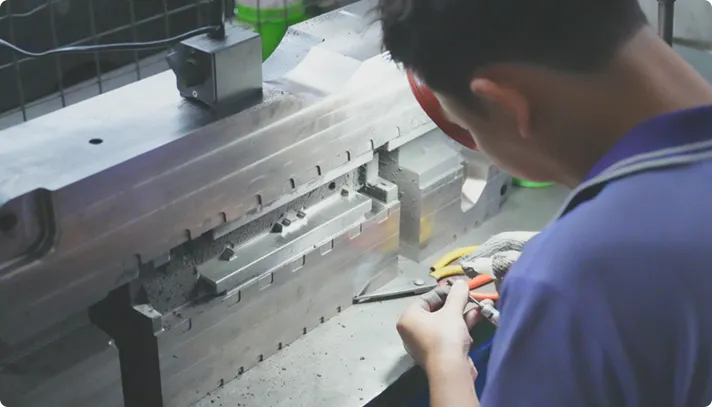

Manual Grinding

Complex Detail Handling

Manual grinding allows operators to focus on intricate, detailed areas of parts that may be difficult for machines to handle, ensuring precision where needed.

Adaptability to Different Materials

Manual grinding can be adjusted based on the material type and specific project requirements, offering flexibility when working with a variety of metals and alloys.

Enhanced Control and Finishing Quality

Skilled operators have more control over the grinding process, resulting in higher-quality finishes and the ability to address imperfections that might be missed by automated processes.

Create the perfect metalworking for you with our custom services

Deburring Department Workshop

The deburring department at Yuhui is equipped with state-of-the-art machinery and staffed by experienced professionals, delivering top-tier surface finishing services to ensure high-quality products with an exceptional appearance. We utilize industry-leading vibratory finishing and polishing equipment to efficiently and precisely remove burrs and enhance surface smoothness. Our team is skilled in adjusting processes to meet specific client requirements, including optional sandblasting for those seeking unique surface textures. Dedicated to meticulous attention to detail, our deburring department ensures that every product meets or exceeds industry standards for quality and finish.

27 +years

Of experience

2500T

Capable of producing

30000 +㎡

Production Workshop

Small Molded Parts with in Days

Our complete CNC aluminum service will accompany your aluminum machining project from the prototype construction to the end aluminum parts manufacturing.

Get a Quote

Grinding Process for Sustainable Operations

At Yuhui Die Casting, we offer sustainable grinding processes that ensure both high production efficiency and environmental responsibility. Our approach includes:

Energy-efficient Equipment and Optimized Processes

We utilize energy-saving grinding equipment and optimize the entire process to reduce power consumption and material waste. This not only lowers production costs but also helps to minimize carbon footprints.

Waste Recycling and Reuse

Waste generated during grinding, such as abrasives, dust, and metal shavings, is effectively collected, sorted, and recycled. This reduces waste disposal and improves resource utilization.

Use of Eco-friendly Materials and Abrasives

We choose eco-friendly abrasives and materials that not only reduce environmental impact but also ensure our products comply with green standards and regulatory requirements.

Process Optimization and Automation

By integrating automated equipment with manual operations, we eliminate unnecessary production steps, optimize the process, and improve production efficiency while minimizing scrap rates.

Employee Training and Safety Management

We provide employees with training on environmental protection and safety to ensure that operations are safe and environmentally conscious, protecting both workers and the environment.

Through these practices, we maintain a sustainable and eco-friendly grinding process while delivering high-quality products and meeting global environmental standards.

Material

Aluminum Alloy

Aluminum casting offers a lightweight, corrosion-resistant solution with excellent thermal conductivity and recyclability, making it suitable for a wide range of applications.

Aluminum ADC12, ADC6, A360, A380

Zinc Alloy

Zinc alloy casting provides high precision and excellent flowability for intricate designs, along with good corrosion resistance and lower production costs.

Zinc Zamak 3, Zamak 5, Zamak 2, ZA8

Eight Processes

High-accuracy aluminum and zinc alloy parts produced with state-of-the-art die casting machines ranging from 88T to 2000T.

Read More

With machines from 88T to 2000T, we produce high-accuracy aluminum and zinc alloy parts efficiently.

Read More

Over 50 CNC machines, including 3-axis, 4-axis, and 5-axis, deliver precise and efficient machining for complex components.

Read More

A combination of manual and automated deburring techniques ensures smooth, defect-free surfaces for optimal performance.

Read More

Post-casting reshaping and alignment guarantee dimensional accuracy and structural integrity.

Read More

Comprehensive finishing solutions, including powder coating, spray painting, and UV coating, ensure superior durability and aesthetics.

Read MoreSolution

Product

FAQ

Q: What deburring methods do you use?

+ -A: We utilize various deburring methods, including manual deburring, mechanical deburring (grinding, tumbling), thermal deburring (TEM), and chemical deburring.

Q: How do you prevent surface damage during deburring?

+ -A: We select appropriate deburring tools and methods based on material characteristics and strictly control processing time to ensure no surface damage.

Q: Can you handle parts with complex shapes?

+ -A: Yes, our mechanical and chemical deburring techniques can effectively process complex structures and internal cavities.

Q: Will deburring affect the dimensional tolerance of the part?

+ -A: We conduct precise measurements before and after deburring to ensure that dimensional tolerances remain within customer specifications.

Q: Do you offer surface finishing services after deburring?

+ -A: Yes, we provide various surface treatments after deburring, such as anodizing, and coating.

Q: How do you handle deburring for batch production?

+ -A: We utilize automated deburring equipment, such as vibratory finishing machines and sandblasting machines, to enhance efficiency and ensure consistency.

Q: Does deburring generate residues? How do you handle them?

+ -A: We use high-pressure air blowing and ultrasonic cleaning to thoroughly remove residues and ensure parts are clean.

Q: Can you provide customized deburring solutions for different materials?

+ -A: Yes, we offer specialized deburring solutions based on the material of the part (such as aluminum alloys, stainless steel, and brass) to achieve optimal results.

Q: Is your deburring process suitable for precision components?

+ -A: Yes, our deburring process is applicable to high-precision components and can be combined with CNC machining to ensure strict edge quality standards.

Q: Do you use robotic polishing for deburring?

+ -A: Yes, we have robotic polishing systems that provide efficient and consistent deburring and surface finishing.

Put Your Parts Into Production Today

Get a Quote

Get in Touch

If you cannot find a suitable product, please leave a message or contact us. We have a dedicated technical team to serve you.