What is Mold Manufacturing?

Mold manufacturing is the core of the die-casting process, involving the transformation of design specifications into a physical mold. Molds play a critical role in die casting, shaping molten aluminum alloy into high-precision metal parts. A well-designed mold ensures product consistency, dimensional accuracy, and surface quality, directly impacting production efficiency and cost management.

Pre-Project Evaluation & Development Support

Yuhui has been deeply involved in the industry for more than 20 years, with professional mold design. At the initial stage of mold manufacturing, Yuhui Die Casting offers comprehensive project evaluation and development support to ensure that each mold fully meets technical requirements and optimizes production efficiency.

Requirement Assessment

We start by consulting with clients to understand key specifications such as functionality, material, dimensions, precision, and production volume.

Based on application needs, we assess mold feasibility and recommend optimal solutions tailored to the client's requirements.

Design Feasibility Analysis

Utilizing advanced simulation software (like Moldflow), our team analyzes the design for potential casting challenges, such as porosity or cold shut, and proposes design adjustments to mitigate issues.

We evaluate geometric complexities and thickness variations to ensure the design supports seamless die-casting production.

Process Recommendations

Our engineers provide recommendations for gating, cooling, and venting systems that enhance mold performance and lifespan.

For complex or intricate components, we offer precise machining plans supported by experimental data to ensure optimal mold output.

Material Selection Support

We recommend suitable mold steel options that ensure exceptional durability, heat resistance, and extended mold life.

Key components receive specialized treatments for enhanced wear resistance and corrosion protection.

Molding Manufacturing Network

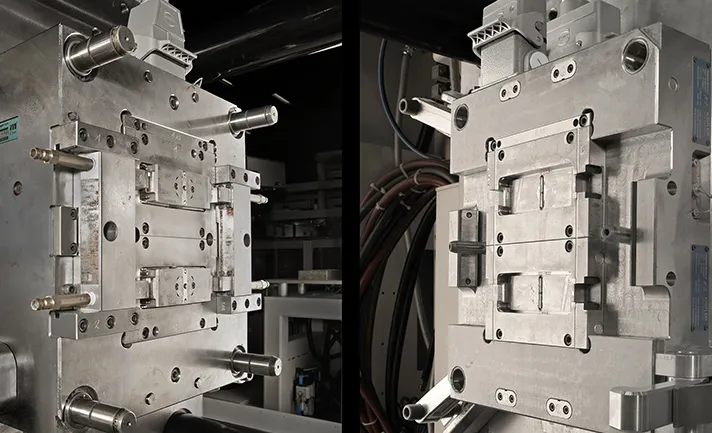

Mold Division is equipped with a comprehensive range of advanced machinery, including multiple CNC machines, EDMs, wire-cut machines, grinders, milling machines, die spotting machines, and CMMs. Capable of producing large molds ranging from 180T to 2500T, our mold division leverages nearly 30 years of experience to deliver outstanding mold solutions to our clients. Each project begins with a detailed mold quotation, accompanied by professional mold flow analysis to identify and resolve potential issues early on. Every mold includes a custom mold setup report to ensure optimal functionality and precision. Our team conducts full dimensional inspections on all products to guarantee they meet the highest industry standards.

27 +years

Of experience

2500T

Capable of producing

20000 +㎡

Production Workshop

Small Molded Parts with in Days

Our complete CNC aluminum service will accompany your aluminum machining project from the prototype construction to the end aluminum parts manufacturing.

Get a Quote

Complete Mold Development Software

Computer aided design development/Simulation die casting process analysis/precision machining dimensional drawing processing

Efficient. Effective. Exceptional The YuHui Mold Manufacturing Process

Mold manufacturing process is meticulously designed to ensure that every project, from design to final product, is clear, efficient, and meets customer requirements.

Design

Manufacturing

Trial Mold

Final Product

Design

In this phase, we communicate in depth with our clients to conduct requirement assessments, gathering critical information about product functionality, materials, dimensions, and production quantities. Our engineers utilize advanced design software to create design models and perform simulation analyses to predict how the molds will perform in production, ensuring potential issues are identified and resolved early in the design process. This phase lays a solid foundation for the subsequent manufacturing steps.

Contact Us

Manufacturing

The mold manufacturing workshop has a series of advanced mold making equipment including optical three-dimensional measuring instrument, precision engraving machine, CNC milling machine, machining center, EDM machine, precision grinder, etc. Mold development realizes full 3D design, full parameter mold flow analysis, and standardized production operations, which can guarantee the rationality and reliability of the mold development and production process to the greatest extent.

Contact Us

Trial Mold

The trial mold phase is a critical step in the mold manufacturing process. During this phase, we perform initial tests on the mold, adjusting various parameters to ensure it can produce the required products smoothly. Based on the trial results, our team makes necessary optimizations and adjustments to ensure that the final product's quality and performance reach their peak.

Contact Us

Final Product

We have the right to import and export die-casting molds and products. The mold factory has complete production equipment. In addition to basic mold making equipment, we have first-class product processing equipment, high-quality engineering and management personnel, and can produce more than 60 sets of molds of various sizes per month.

Contact Us

Material

Aluminum Alloy

Aluminum casting offers a lightweight, corrosion-resistant solution with excellent thermal conductivity and recyclability, making it suitable for a wide range of applications.

Aluminum ADC12, ADC6, A360, A380

Zinc Alloy

Zinc alloy casting provides high precision and excellent flowability for intricate designs, along with good corrosion resistance and lower production costs.

Zinc Zamak 3, Zamak 5, Zamak 2, ZA8

Eight Processes

High-accuracy aluminum and zinc alloy parts produced with state-of-the-art die casting machines ranging from 88T to 2000T.

Read More

With machines from 88T to 2000T, we produce high-accuracy aluminum and zinc alloy parts efficiently.

Read More

Over 50 CNC machines, including 3-axis, 4-axis, and 5-axis, deliver precise and efficient machining for complex components.

Read More

A combination of manual and automated deburring techniques ensures smooth, defect-free surfaces for optimal performance.

Read More

Post-casting reshaping and alignment guarantee dimensional accuracy and structural integrity.

Read More

Comprehensive finishing solutions, including powder coating, spray painting, and UV coating, ensure superior durability and aesthetics.

Read MoreSolution

Product

FAQ

Q: What is the mold design process?

+ -A: Our mold design process includes requirement analysis, 3D modeling, DFM (Design for Manufacturability) analysis, CAE mold flow simulation, engineering review, and final design confirmation.

Q: What types of molds can you manufacture?

+ -A: We specialize in aluminum and zinc alloy die-casting molds, designed for automotive, medical, telecommunications, and other precision industries.

Q: What materials do you use for mold manufacturing?

+ -A: We primarily use high-performance tool steels such as H13, SKD61, and 8407, selecting the best material based on customer requirements.

Q: How do you ensure the longevity of your molds?

+ -A: We use high-quality steel, advanced heat treatment processes, and optimized mold designs, ensuring a lifespan of 50,000 to over 500,000 shots.

Q: Do you provide DFM reports?

+ -A: Yes, we provide DFM reports during the design phase to help customers optimize product designs, enhance manufacturability, and reduce production costs.

Q: What software do you use for mold flow analysis?

+ -A: We utilize advanced CAE simulation tools such as Magma, Flow-3D, and AutoForm to optimize material flow, cooling efficiency, and minimize shrinkage issues.

Q: What is your typical mold lead time?

+ -A: The standard lead time is 4 to 6 weeks, depending on the complexity of the mold and specific customer requirements.

Q: Can you manufacture multi-cavity molds?

+ -A: Yes, we design and manufacture single-cavity, dual-cavity, and multi-cavity molds to maximize production efficiency.

Q: What is the machining accuracy of your molds?

+ -A: Our CNC machining accuracy reaches ±0.01mm, ensuring high precision for complex mold requirements.

Q: Do you provide mold trials and sample parts?

+ -A: Yes, we conduct T0, T1, and T2 mold trials before final delivery and provide sample parts for customer approval.

Put Your Parts Into Production Today

Get a Quote

Get in Touch

If you cannot find a suitable product, please leave a message or contact us. We have a dedicated technical team to serve you.